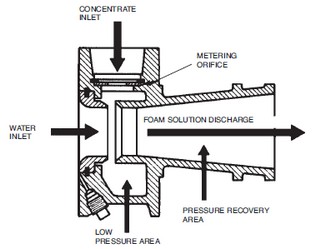

Balanced Pressure Proportioning is the most common method used for fixed system applications where pressure or flow can vary with demand. There are two basic types – Bladder Tanks and Pump Systems using Balanced Pressure Proportioners. All balanced pressure systems use a modified venturi device called a proportioner or ratio controller. The proportioners are available in a variety of sizes and styles to match required flow ranges and pipe sizes. As water flows through the proportioner nozzle, a low pressure area is created. It is in this low pressure area that the pressurized concentrate mixes with the water stream. A metering orifice, at the concentrate inlet, regulates the rate of concentrate flow and thus determines the percentage of concentrate in the foam solution. Balanced pressure proportioning systems require the foam concentrate pressure to be balanced with the water pressure at the proportioner inlets. This balance meters the proper amount of foam concentrate into the water stream.

Balanced Pressure Proportioning is the most common method used for fixed system applications where pressure or flow can vary with demand. There are two basic types – Bladder Tanks and Pump Systems using Balanced Pressure Proportioners. All balanced pressure systems use a modified venturi device called a proportioner or ratio controller. The proportioners are available in a variety of sizes and styles to match required flow ranges and pipe sizes. As water flows through the proportioner nozzle, a low pressure area is created. It is in this low pressure area that the pressurized concentrate mixes with the water stream. A metering orifice, at the concentrate inlet, regulates the rate of concentrate flow and thus determines the percentage of concentrate in the foam solution. Balanced pressure proportioning systems require the foam concentrate pressure to be balanced with the water pressure at the proportioner inlets. This balance meters the proper amount of foam concentrate into the water stream.

Bladder Tank System

Balanced pressure bladder tank systems use a pressure-rated tank with an internal nylonreinforced elastomeric bladder. System water pressure is used to squeeze the bladder containing the foam concentrate providing pressurized concentrate to the proportioner. The resulting foam solution is piped to discharge devices protecting the hazard area. A distinct advantage of bladder tanks is that no external power supply is required other than a pressurized water source. However, because the bladder tank is pressurized during operation, it cannot be conveniently recharged during discharge. Because of their simple design, bladder tanks require very little maintenance.

Balanced pressure bladder tank systems use a pressure-rated tank with an internal nylonreinforced elastomeric bladder. System water pressure is used to squeeze the bladder containing the foam concentrate providing pressurized concentrate to the proportioner. The resulting foam solution is piped to discharge devices protecting the hazard area. A distinct advantage of bladder tanks is that no external power supply is required other than a pressurized water source. However, because the bladder tank is pressurized during operation, it cannot be conveniently recharged during discharge. Because of their simple design, bladder tanks require very little maintenance.

Balance Pressured Pump Proportioning

Balance pressure pump proportioning systems use atmospheric foam concentrate storage tanks The tank is not pressure rated and may be constructed of mild steel, fiberglass-reinforced plastic, or polyethylene plastic. Instead of using pressurized water as with bladder tanks, the foam liquid is pumped to the proportioner. An automatic pressure balancing valve regulates the foam concentrate pressure to match the water pressure. A duplex pressure gauge provides continuous monitoring of both water and concentrate pressures. The system can also be operated manually to control the pressures and isolate the automatic balancing valve. Positive displacement pumps are used with these systems to allow maximum efficiency for liquids of varying viscosity. The size of pumps and drivers will vary depending on the application and the type of foam concentrate used.

Instead of using pressurized water as with bladder tanks, the foam liquid is pumped to the proportioner. An automatic pressure balancing valve regulates the foam concentrate pressure to match the water pressure. A duplex pressure gauge provides continuous monitoring of both water and concentrate pressures. The system can also be operated manually to control the pressures and isolate the automatic balancing valve. Positive displacement pumps are used with these systems to allow maximum efficiency for liquids of varying viscosity. The size of pumps and drivers will vary depending on the application and the type of foam concentrate used.

In-Line Balanced Pressure Proportioner

The in-line balanced pressure proportioner is similar to the pump skid previously described except that it is a separate assembly that offers the advantage of proportioning the foam concentrate at a location remote from the tank and pump. Like the pump skid, the proportioner assembly incorporates an automatic pressure balancing valve, duplex gauge, and hand-operated valves for optional manual pressure regulation. A pressure control valve, located in the return line to the foam concentrate storage tank, maintains constant pressure in the supply manifold that is 15 to 20 psi (103 to 138 kPa) higher than the water pressure to the proportioner. Multiple in-line balanced pressure proportioners can be supplied from a single foam pump to protect several hazard areas. By adding an automated valve to each proportioner, either foam discharge or water only discharge can be selected.

The in-line balanced pressure proportioner is similar to the pump skid previously described except that it is a separate assembly that offers the advantage of proportioning the foam concentrate at a location remote from the tank and pump. Like the pump skid, the proportioner assembly incorporates an automatic pressure balancing valve, duplex gauge, and hand-operated valves for optional manual pressure regulation. A pressure control valve, located in the return line to the foam concentrate storage tank, maintains constant pressure in the supply manifold that is 15 to 20 psi (103 to 138 kPa) higher than the water pressure to the proportioner. Multiple in-line balanced pressure proportioners can be supplied from a single foam pump to protect several hazard areas. By adding an automated valve to each proportioner, either foam discharge or water only discharge can be selected.