An automatic sprinkler system is designed to distribute water or foam solution to a specific hazard area. The application rate, commonly referred to as ‘‘ density,’’ is frequently expressed in units of gallons per minute per square foot ( gpm/ ft2) or liters per minute per square meter (Lpm/m2) of area.

The worst potential fire situation is generally used to determine the number of sprinkler heads discharging. This, in turn, determines the water supply demand; and in the case

of foam sprinkler systems, the required amount of foam liquid concentrate. Characteristics of some flammable products may require higher densities and special foam liquid

concentrates.

Areas protected by sprinkler systems are usually given a class of occupancy (light, ordinary, or high hazard). The class of occupancy relates to the probable number of sprinkler

heads that may operate in a particular fire situation and governs the maximum spacing allowed between sprinkler heads. The sprinkler head provides for a nearly uniform distribution of water or expanded foam over a given area. The solution strikes a deflector and is broken into a circular pattern of distribution. Spacing of sprinkler heads results in overlapping patterns to ensure uniform coverage and effective fire control.

Pipe sizing to the sprinkler heads is commonly determined by hydraulic calculations to assure an adequate supply of water and uniform distribution from the sprinkler heads. The standard addressing sprinkler system design is NFPA Standard 13 or BS EN12845. Additional guidance for foam systems design is contained within NFPA Standards 11, 16, and 30.

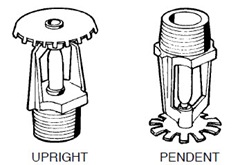

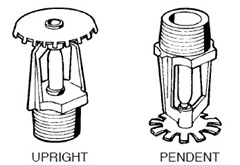

Types of Sprinkler Head

Conventional sprinkler heads

Conventional sprinklers heads are available for either upright or pendent installation. A heat sensitive element, consisting of either a fusible link or frangible glass bulb, is rated for a specific operating temperature. A standard orifice sprinkler is 15mm; however, various small and large orifice sprinklers are available to achieve the desired density with the available water supply pressure.

Conventional sprinklers heads are available for either upright or pendent installation. A heat sensitive element, consisting of either a fusible link or frangible glass bulb, is rated for a specific operating temperature. A standard orifice sprinkler is 15mm; however, various small and large orifice sprinklers are available to achieve the desired density with the available water supply pressure.

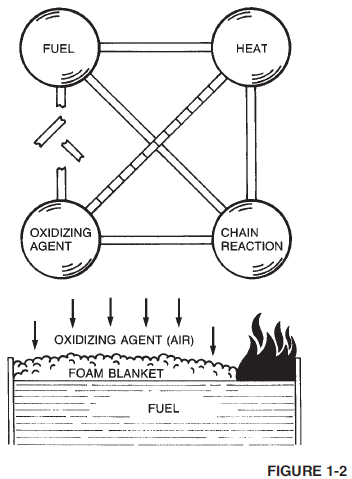

Conventional open sprinkler heads, without the heat-sensitive element, are used for total area flooding “deluge” systems. In applications using AFFF concentrates, the conventional sprinkler is acceptable. The UL listing directory should be consulted to ensure the sprinkler head is listed with the manufacturer’s foam concentrate.

Acceptable foam quality is expected from conventional sprinkler heads of similar design to those listed. These sprinklers cannot be used with protein or fluoroprotein base foam concentrates which require air aspirated discharge devices.

Foam/water sprinkler heads

Foam/water sprinkler heads are open type and generate air aspirated foam by drawing air into the foam solution stream. The sprinkler head is available for either

Foam/water sprinkler heads are open type and generate air aspirated foam by drawing air into the foam solution stream. The sprinkler head is available for either

upright or pendent mounting and may be used with either foam or water. Patterns of coverage are similar to conventional sprinkler heads; however, only a 3/8 in. orifice is

available corresponding to a K-Factor of 3.0.

Types of Sprinkler Systems

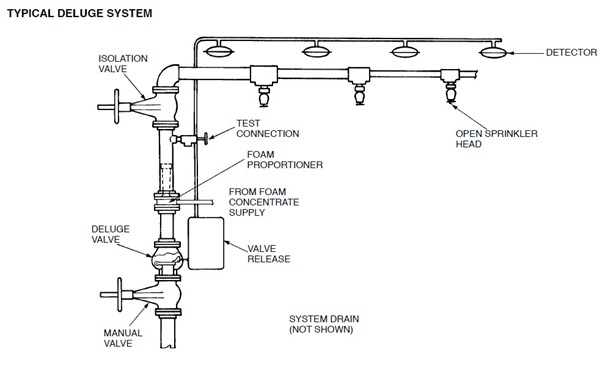

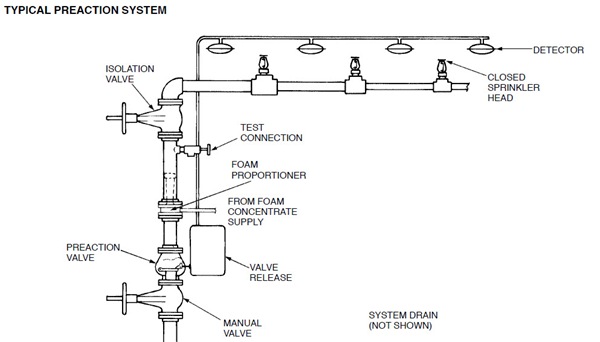

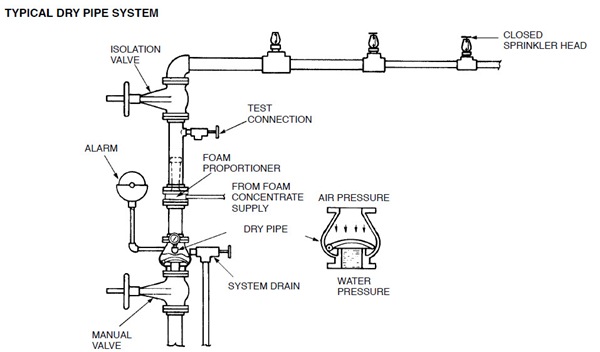

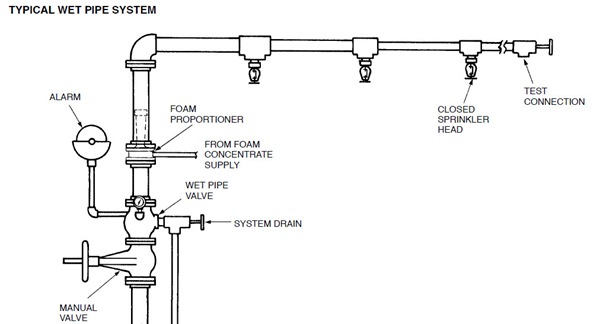

Sprinkler systems can be either closed-head or open-head (deluge) systems using conventional sprinkler heads. Sprinkler systems using foam/water sprinkler heads can

only be open-head systems as these sprinklers are not available with heat-sensitive elements. Closed-head sprinkler systems can be of three different types: wet pipe, dry pipe, or preaction. An AFFF foam can be used in any closed-head sprinkler system as covered by NFPA Standard 16 – Foam/ Water Sprinkler Systems.

The following types of system are generally used

Wet Pipe System - click here for further information

Dry Pipe System – click here for further information

Preaction System – click here for further information

Deluge System – click here for further information

Technical Datasheet Downloads

Approved Sprinkler Head list for Foam Concentrates