In the past there have been two problems associated with bladder tanks – the possibility of the bladder rupturing and also the inability to refill the unit during operation because it is pressurised.

In the past there have been two problems associated with bladder tanks – the possibility of the bladder rupturing and also the inability to refill the unit during operation because it is pressurised.

Both of these problems have now been tackled and resolved by SKUM.

Unique fixing and support methods now employed by SKUM now ensure the integrity of the bladder while still maintaining the ease of bladder installation and operation.

The problem of refilling during operation has also been overcome by providing a pressurised source of foam concentrate from a mobile unit as an optional extra to the basic tank supply. The optional mobile unit also provides a simple means of refilling after operation.

The list of advantages for bladder tank usage has now been re-written as follows:-

- Few moving parts

- Low Pressure Drop

- Variable Flow capability

- Can be used with all types of foam concentrate

- No external power source required

- Can be refilled during operation

- Can easily be used in automatic systems

- Can meet the requirements of all internationally recognised design codes

Please contact us for more information on +353 1 494 1429

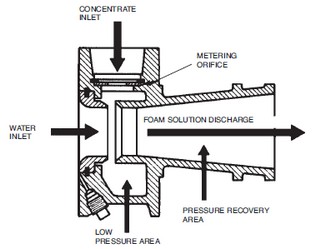

Balanced Pressure Proportioning is the most common method used for fixed system applications where pressure or flow can vary with demand. There are two basic types – Bladder Tanks and Pump Systems using Balanced Pressure Proportioners. All balanced pressure systems use a modified venturi device called a proportioner or ratio controller. The proportioners are available in a variety of sizes and styles to match required flow ranges and pipe sizes. As water flows through the proportioner nozzle, a low pressure area is created. It is in this low pressure area that the pressurized concentrate mixes with the water stream. A metering orifice, at the concentrate inlet, regulates the rate of concentrate flow and thus determines the percentage of concentrate in the foam solution. Balanced pressure proportioning systems require the foam concentrate pressure to be balanced with the water pressure at the proportioner inlets. This balance meters the proper amount of foam concentrate into the water stream.

Balanced Pressure Proportioning is the most common method used for fixed system applications where pressure or flow can vary with demand. There are two basic types – Bladder Tanks and Pump Systems using Balanced Pressure Proportioners. All balanced pressure systems use a modified venturi device called a proportioner or ratio controller. The proportioners are available in a variety of sizes and styles to match required flow ranges and pipe sizes. As water flows through the proportioner nozzle, a low pressure area is created. It is in this low pressure area that the pressurized concentrate mixes with the water stream. A metering orifice, at the concentrate inlet, regulates the rate of concentrate flow and thus determines the percentage of concentrate in the foam solution. Balanced pressure proportioning systems require the foam concentrate pressure to be balanced with the water pressure at the proportioner inlets. This balance meters the proper amount of foam concentrate into the water stream.

The in-line balanced pressure proportioner is similar to the pump skid previously described except that it is a separate assembly that offers the advantage of proportioning the foam concentrate at a location remote from the tank and pump. Like the pump skid, the proportioner assembly incorporates an automatic pressure balancing valve, duplex gauge, and hand-operated valves for optional manual pressure regulation. A pressure control valve, located in the return line to the foam concentrate storage tank, maintains constant pressure in the supply manifold that is 15 to 20 psi (103 to 138 kPa) higher than the water pressure to the proportioner.

The in-line balanced pressure proportioner is similar to the pump skid previously described except that it is a separate assembly that offers the advantage of proportioning the foam concentrate at a location remote from the tank and pump. Like the pump skid, the proportioner assembly incorporates an automatic pressure balancing valve, duplex gauge, and hand-operated valves for optional manual pressure regulation. A pressure control valve, located in the return line to the foam concentrate storage tank, maintains constant pressure in the supply manifold that is 15 to 20 psi (103 to 138 kPa) higher than the water pressure to the proportioner.